Economic Geography Part II

(Industrial Locational Factors Part I)

Factors responsible for the location of primary, secondary, and tertiary sector

1. Primary, Secondary and Tertiary Sectors 5

1.1.3 Commercial Livestock Rearing 8

1.1.4 Subsistence Agriculture 9

1.1.5 Plantation Agriculture 10

1.1.6 Extensive Commercial Grain Cultivation 11

1.1.9 Mediterranean Agriculture 14

1.1.10 Market Gardening and Horticulture 14

1.1.11 Co-operative Farming 15

1.2.1 Modern Manufacturing Industry 16

1.2.2 Classification of Manufacturing Industries 16

1.2.3 Foot Loose Industries 18

1.2.4 Traditional Large-Scale Industrial Regions 19

1.2.5 Concept of High Technology Industry 19

1.3.1 Types of tertiary activities 20

1.4.1 The Quaternary Sector 23

1.5. Some of the factors influencing locations of various sectors (industries) 24

1.5.2 Access to Raw Materials 24

1.5.3 Access to energy sources 25

1.5.5 Access to Transportation and Communication Facilities 25

1.5.6 Supply of cheap labour and skilled workforce 25

1.5.7 Access to Agglomeration Economies/Links between Industries 26

2.1.2 What exactly happens in a blast furnace? 29

2.2. Factors that influence the location of Iron and Steel Industry 32

2.2.2 Transportation: Near coastal areas for cheaper raw material imports 38

2.2.3 Transport Cost Minimization 38

2.2.4 Access to markets: Mini Steel plants 39

2.2.5 Economies of Linkages and Agglomerations: Duluth-Detroit-Cleveland-Pittsburgh 39

2.2.8 Quality of ore, economies of scale, Cheap labour 41

2.2.10 Rules and regulations 42

2.2.13 Distribution of Iron and Steel Industry 43

3.1. Factors that affect the location of the cotton textile industry 45

3.2. Cotton Textile Manufacturing Regions of the World 47

3.2.1 Factors responsible for the Localization of the British Cotton Textile Industry 47

3.2.2 Factors responsible for the Localization of the American Cotton Textile Industry 51

3.2.3 Factors responsible for the Localization of the Japanese Cotton Textile Industry 54

3.2.4 Factors responsible for the Localization of the German Cotton Textile Industry. 55

3.2.5 Factors responsible for the Localization of Russian Cotton Textile Industry 56

3.2.6 Factors responsible for the Localization of the Chinese Cotton Textile Industry 57

3.3. Cotton Textile Industry in India 59

3.3.2 Factors responsible for the Localization of the Cotton Textile Industry in India 59

3.3.3 Issues Faced by the Cotton Textile Industry in India 63

3.4. Top cotton producers, importers and exporters 64

4. Woollen Textile Industry 64

4.1. Factors that affect commercial wool production 65

4.1.1 Major wool producing regions 65

4.2. Factors that affect the location of the woollen textile industry 66

4.2.2 U.K. – The Rise and Fall 67

4.3. Indian Woollen Textile Industry 68

4.3.3 Problems of Indian woollen textile industry 70

5.1. Factors responsible for the concentration of Jute Industry in the Hooghly Basin 71

5.2. Issues faced by the jute industry 72

5.3. Future positives for the jute industry 72

5.4. Top jute producing, exporting and importing countries 72

6.1. Silk Industry in India 74

6.1.1 Factors Responsible for the Localization of the Silk Industry in Karnataka 75

6.1.2 Factors Responsible for the Localization of the Silk Industry in Varanasi 76

6.1.3 Factors Responsible for the Localization of the Silk Industry in Kanchipuram 76

6.1.4 Factors Responsible for the Localization of Silk Industry in Jammu and Kashmir 77

6.1.5 Issues faced by Indian Silk Industry 78

6.2. Factors Responsible for the Localization of the Silk Industry in China 78

6.3. Silk Industry Outside India and China 79

7.1. Major Factors that influence the location of sugar industry 82

7.2.1 The rise and fall of Cuban Sugar Industry 85

7.3. Sugar Industry in Peninsular India vs Sugar Industry in North India 85

7.4. Challenges faced by the sugar industry in India 87

8.2. Factors that determine the location of the tea industry 88

8.3. Major tea producing areas in India 89

8.3.1 Tea industry of the Darjeeling district 90

8.3.2 Tea industry of the Western Ghats and Nilgiri Hills of TN, Kerala, and Karnataka 91

8.4. The rise and fall of the British Tea Industry 92

9.2. Factors that determine the location of coffee industry 93

9.3. Coffee Industry in Brazil 94

9.4. Coffee Industry in Nilgiris 95

10.1.1 Evolution of the natural rubber industry 96

10.2.1 Evolution of the synthetic rubber industry 97

10.4. Southeast Asian vs South American Natural Rubber Industry 98

11. Lumbering, Pulp and Paper Industry 101

11.1. Lumbering Industry in the Temperate Regions vs Lumbering Industry in the Tropical Regions 101

11.2. Factors affecting the location of the sawmills (lumbering) industry 103

11.3. Factors affecting the location of paper pulp industry 105

11.4. Lumbering, Pulp and Paper Industry in Canada 106

11.5. Lumbering, Pulp and Paper Industry in Russia 107

11.5.1 What are the challenges faced by Russia in exploiting its vast Siberian Taiga forests? 108

11.6. Lumbering, Pulp and Paper Industry in U.S.A. 109

11.7. Lumbering, Pulp and Paper Industry in other regions 110

11.8. Lumbering, Pulp and Paper Industry in India 111

11.8.1 Paper Industry in India 111

11.8.2 Problems of Indian Paper Industry 112

11.9. International lumber, pulp and paper imports and exports 113

12. Commercial Marine Fishing Industry 113

12.1. Marine Capture Fisheries 113

12.2. Factors that create the most fertile marine fishing grounds 115

12.3. Factors that determine the location of the commercial fishing industry 116

12.4. The major commercial marine fishing grounds of the world 118

12.4.1 North-East Atlantic Region 118

12.4.2 North-West Atlantic Region 118

12.4.3 North-West Pacific Region 119

12.4.4 China, India and South-East Asia 121

12.4.5 Southern Hemisphere (Peru and Chile Coast) 122

12.4.6 Commercial marine fishing is little developed in the southern hemisphere. Explain 123

12.4.7 Commercial marine fishing is little developed in the tropics. Explain 123

Primary, Secondary and Tertiary Sectors

- Economic activities are broadly grouped into primary, secondary, tertiary and quaternary activities.

Primary Activities

- Primary activities are directly dependent on the environment as these refer to utilisation of earth’s resources such as land, water, vegetation, building materials, minerals, etc.

- It thus includes hunting, gathering, pastoral activities, fishing, forestry, agriculture, mining, quarrying, etc.

- Industries that are involved in primary economic activities are called as primary industries.

Hunting and Gathering

- Gathering is practised in regions with harsh climatic conditions.

- It involves primitive societies that extract from both plants and animals to satisfy their basic needs.

- The yield per person is meagre and little, or no surplus is produced.

- Gathering is practised in:

- high latitude zones which include northern Canada, northern Eurasia and southern Chile.

- Low latitude zones such as the Amazon Basin, tropical Africa, Northern fringe of Australia and the interior parts of Southeast Asia.

- They use various parts of the plants, e.g., the bark is used for quinine, tanin extract and tree trunk yield rubber, gums and resins.

- The chewing gum after the flavour is gone is called Chicle — it is made from the juice of zapota tree.

- In modern times some gathering is market-oriented and has become commercial.

- However, synthetic products often of better quality and at lower prices have replaced many items supplied by the gatherers in tropical forests.

Image Source: NROER

Pastoralism

- At some stage in history, as hunting was unsustainable, humans began the domestication of animals.

- People living in different climatic conditions selected and domesticated animals found in those regions.

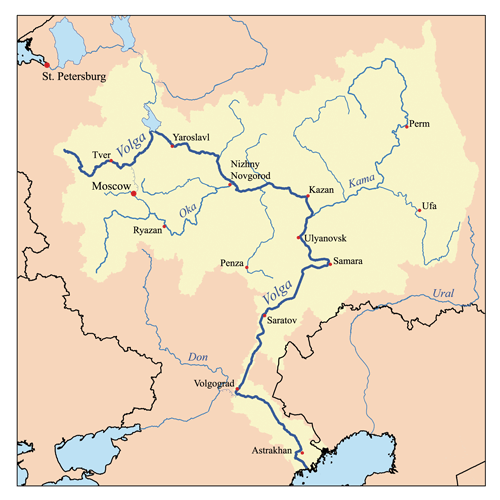

Nomadic Herding (pastoral nomadism)

- Nomadic herding is a primitive subsistence activity.

- They move from place to place along with their livestock, depending on the availability of pastures & water.

- A wide variety of animals is kept in different regions.

- In tropical Africa, cattle are the most important livestock, while in Sahara and Asiatic deserts, sheep, goats and camel are reared.

- In the mountainous areas of Tibet and Andes, yak and llamas and in the Arctic and sub-Arctic regions, reindeer are the most important animals.

- Pastoral nomadism is associated with three important regions.

- The core region extends from the Atlantic shores of North Africa eastwards across the Arabian Peninsula into Mongolia and Central China.

- The second region extends over the tundra region of Eurasia.

- In the southern hemisphere there are small areas in South-west Africa and on the island of Madagascar.

Image Source: NROER

- The process of migration from plain areas to pastures on mountains during summers and again from mountain pastures to plain areas during winters is known as transhumance.

- In mountain regions, such as Himalayas, Gujjars, Bakarwals, Gaddis and Bhotiyas migrate from plains to the mountains in summers and to the plains from the high altitude pastures in winters.

- The number of pastoral nomads has been decreasing due to the imposition of political boundaries.

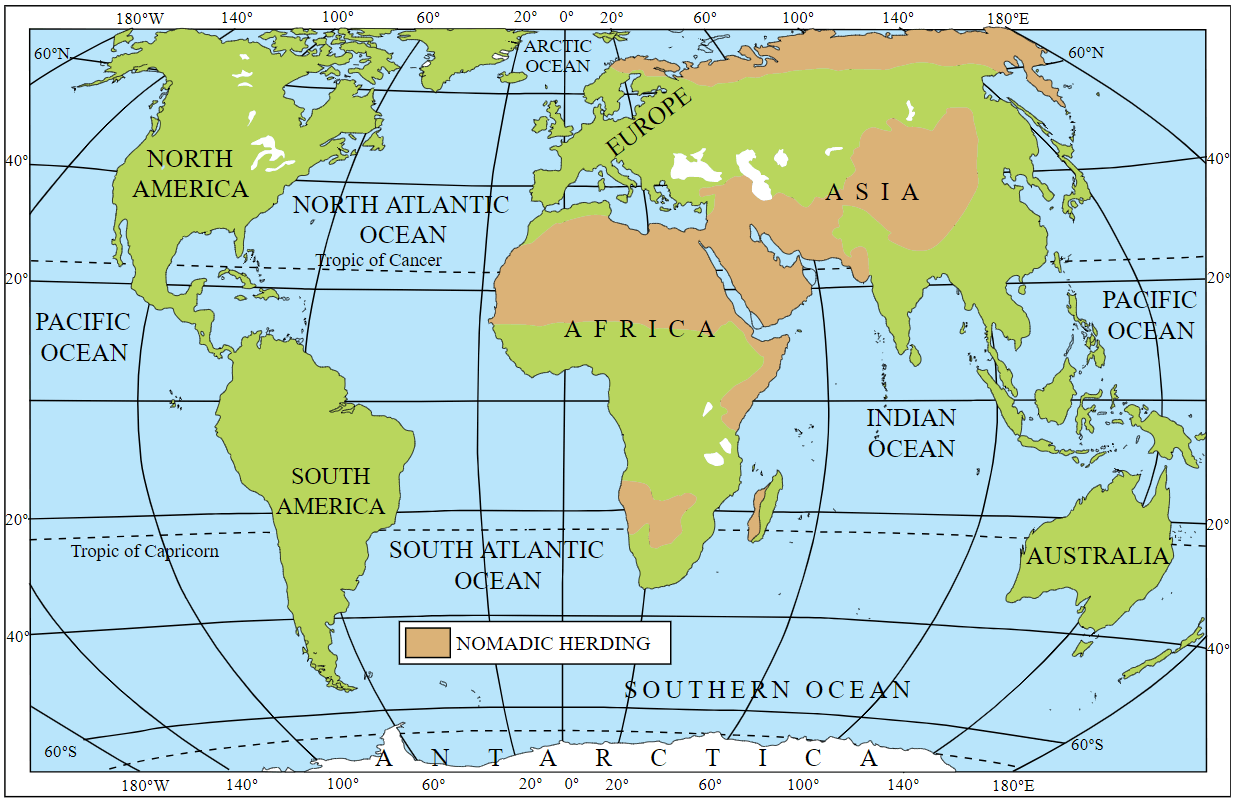

Commercial Livestock Rearing

- Commercial livestock rearing is more organised and capital intensive.

- Commercial livestock ranching is associated with western cultures and is practised on permanent ranches.

- These ranches (a large farm where cattle are bred) cover large areas and are divided into a number of parcels, which are fenced to regulate the grazing.

- When the grass of one parcel is grazed, animals are moved to another parcel.

- This is a specialised activity in which only one type of animal is reared.

- Essential animals include sheep, cattle, goats and horses.

- Meat, wool, hides and skin are processed and packed scientifically and exported world markets.

- Rearing of animals in ranching is organised on a scientific basis.

- The main emphasis is on breeding, genetic improvement, disease control and health care of the animals.

- New Zealand, Australia, Argentina, Uruguay and the United States of America are important countries where commercial livestock rearing is practised.

Image Source: NROER

Subsistence Agriculture

- In subsistence agriculture, almost all the production is consumed locally with little or nothing left for trade.

- Primitive Subsistence Agriculture and Intensive Subsistence Agriculture are the two types.

Primitive Subsistence Agriculture

- Primitive subsistence agriculture or shifting cultivation is widely practised by many tribes in the tropics.

- The vegetation is usually cleared by fire, and the ashes add to the fertility of the soil.

- Shifting cultivation is thus, also called slash and burn agriculture.

- It is prevalent in the tropical region in different names, e.g. Jhuming in Northeastern states of India, Milpa in Central America and Mexico and Ladang in Indonesia and Malaysia.

Intensive Subsistence Agriculture

- This type of agriculture is largely found in densely populated regions of monsoon Asia.

- There are two types of intensive subsistence agriculture.

Intensive subsistence agriculture dominated by wet paddy cultivation

- Landholdings are very small due to the high density of population.

- Farmers work with the help of family labour leading to intensive use of land.

- Use of machinery is limited, and most of the agricultural operations are done by manual labour.

- Farmyard manure is used to maintain the fertility of the soil.

- In this type of agriculture, the yield per unit area is high but per labour productivity is low.

Intensive subsidence agriculture dominated by crops other than paddy

- Due to the difference in relief, climate, soil, etc. it is not practical to grow paddy in parts of monsoon Asia.

- Wheat, soyabean, barley & sorghum are grown in northern China, North Korea and North Japan.

- In India wheat is grown in plains and millets are grown in dry parts of western and southern India.

- Most of the characteristics are similar to that of wet paddy cultivation except that irrigation is often used.

Image Source: NROER

Plantation Agriculture

- Plantation agriculture was introduced by the Europeans in colonies situated in the tropics.

- Plantations are mainly profit-oriented large scale production systems.

- E.g. tea, coffee, cocoa, rubber, cotton, palm, sugarcane, banana & pineapple.

- The characteristic features of this type of farming are

- large estates or plantations,

- large capital investment,

- managerial and technical support,

- scientific methods of cultivation,

- single crop specialisation,

- cheap labour, and

- a good system of transportation which links the estates to the factories and markets.

- The French established cocoa and coffee plantations in west Africa.

- The British set up large

- tea gardens in India and Sri Lanka,

- rubber plantations in Malaysia and

- sugarcane and banana plantations in West Indies.

- Spanish and Americans invested heavily in coconut and sugarcane plantations in the Philippines.

- The Dutch once had a monopoly over sugarcane plantation in Indonesia.

- Some coffee fazendas (large plantations) in Brazil are still managed by Europeans.

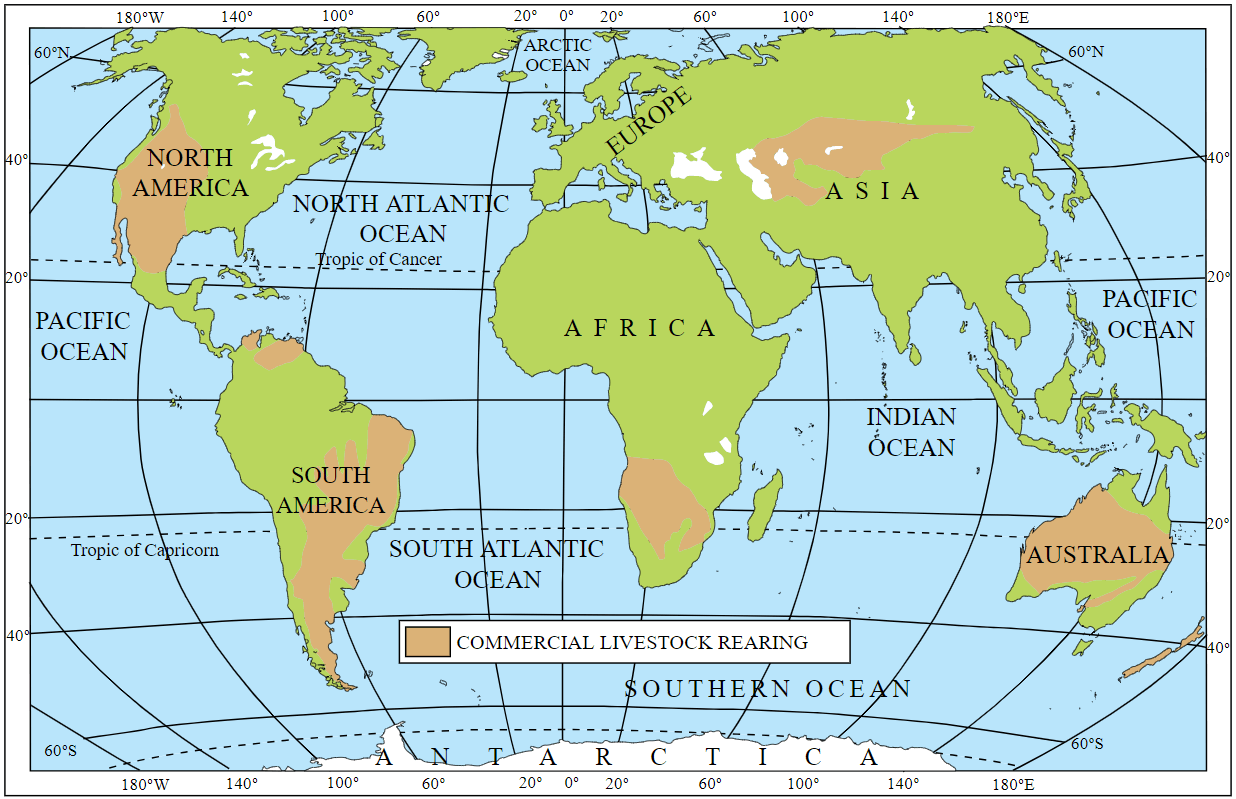

Extensive Commercial Grain Cultivation

- Commercial grain cultivation is practised in the interior parts of semi-arid lands of the midlatitudes.

- Wheat is the principal crop, though other crops like corn, barley, oats and rye are also grown.

- The size of the farm is very large. Therefore entire operations of cultivation are mechanised.

- There is a low yield per acre but high yield per person.

- This type of agriculture is best developed in the Eurasian steppes, the North American Prairies, Pampas of Argentina, Velds of South Africa, the Australian Downs and the Canterbury Plains of New Zealand.

Image Source: NROER

Mixed Farming

- This form of agriculture is found in the highly developed parts of the world, e.g. North-western Europe, Eastern North America, and the temperate latitudes of Southern continents.

- Mixed farms are moderate in size & the crops grown are wheat, barley, oats, maize, fodder & root crops.

- Animal husbandry is an essential component of mixed farming.

- Animals like cattle, sheep, pigs and poultry provide the primary income along with crops.

- Crop rotation and intercropping play an essential role in maintaining soil fertility.

- Mixed farming is characterised by high capital expenditure on farm machinery and building, extensive use of chemical fertilisers and green manures and also by the skill and expertise of the farmers.

Image Source: NROER

Dairy Farming

- Dairy is the most advanced and efficient type of rearing of milch animals.

- It is highly capital intensive.

- Animal sheds, storage facilities for fodder, feeding and milking machines add to the cost of dairy farming.

- Special emphasis is laid on cattle breeding, health care and veterinary services.

- It is highly labour intensive as it involves rigorous care in feeding and milking.

- There is no offseason during the year as in the case of crop raising.

- It is practised near urban centres which provide a neighbourhood market for fresh milk & dairy products.

- The development of transportation, refrigeration, pasteurisation and other preservation processes have increased the duration of storage of various dairy products.

- There are three main regions of commercial dairy farming.

- The largest is North Western Europe the second is Canada, and the third belt includes South Eastern Australia, New Zealand and Tasmania.

Image Source: NROER

Mediterranean Agriculture

- Mediterranean agriculture is highly specialised commercial agriculture.

- It is practised in the countries on either side of the Mediterranean Sea, southern California, central Chile, southwestern parts of South Africa and south and southwestern parts of Australia.

- This region is an important supplier of citrus fruits.

- Viticulture or grape cultivation is a speciality of the Mediterranean region.

- Best quality wines in the world are produced from high-quality grapes in various countries of this region.

- The inferior grapes are dried into raisins and currants. This region also produces olives and figs.

- The advantage of Mediterranean agriculture is that more valuable crops such as fruits and vegetables are grown in winters when there is a great demand in European and North American markets.

Market Gardening and Horticulture

- Market gardening and horticulture specialise in the cultivation of high-value crops such as vegetables, fruits and flowers, solely for the urban markets.

- Farms are small and are located where there are good transportation links with the urban centre.

- It is both labour and capital intensive and lays emphasis on the use of irrigation, HYV seeds, fertilisers, insecticides, greenhouses and artificial heating in colder regions.

- This type of agriculture is well developed in densely populated industrial districts of north-west Europe, northeastern United States of America and the Mediterranean regions.

- The farming where farmers specialise in vegetables only is known as truck farming.

- The distance of truck farms from the market is governed by the distance that a truck can cover overnight.

- The modern development in the industrial regions of Western Europe & North America is factory farming.

- Livestock, particularly poultry and cattle rearing, is done in stalls and pens.

- They fed on manufactured feedstuff and carefully supervised against diseases.

- This requires heavy capital investment, veterinary services and heating and lighting.

Co-operative Farming

- A group of farmers form a co-operative society voluntarily for more efficient and profitable farming.

- Individual farms remain intact, and farming is a matter of cooperative initiative.

- Co-operative societies help farmers, to procure all valuable inputs of farming, sell the products at the most favourable terms and assist in the processing of quality products at cheaper rates.

- The co-operative movement has been successful in many western European countries like Denmark, Netherlands, Belgium, Sweden, Italy etc.

Collective Farming

- It is based on social ownership of the means of production and collective labour.

- Collective farming or the model of Kolkhoz was introduced in erstwhile USSR to improve upon the inefficiency of the previous methods of agriculture and to boost agricultural production for self-sufficiency.

- The farmers used to pool in all their resources like land, livestock and labour.

- They were allowed to retain very small plots to grow crops in order to meet their daily requirements.

Mining

- The actual development of mining began with the industrial revolution.

- Mining is of two types: surface mining (open-cast mining) and underground mining.

- Surface mining is the easiest and the cheapest way of mining minerals that occur close to the surface.

- The output is both large and rapid.

- When the ore lies deep below the surface, the underground mining (shaft method) has to be used.

- In this method, underground galleries from vertical shafts radiate to reach the minerals.

- Minerals are extracted and transported to the surface through these passages.

- It requires specially designed lifts, drills, haulage vehicles, ventilation system for safety and efficiency.

- This method is risky — poisonous gases, fires, floods, and caving lead to fatal accidents.

- The developed economies are retreating from mining, processing and refining stages of production due to high labour costs, while the developing countries with large labour force are becoming more important.

- Several countries of Africa and Asia have over fifty per cent of the earnings from minerals alone.

Secondary Activities

- Secondary activities transform raw materials into valuable products by the processes of processing, manufacturing, and construction.

- In each of these processes, the common characteristics are the application of power, mass production of identical products and specialised labour in factory settings for the production of commodities.

Modern Manufacturing Industry

- Modern large scale manufacturing undertakes mass production of standardised parts by each worker or robot performing only one task repeatedly.

Mechanisation

- Mechanisation refers to using gadgets which accomplish tasks.

- Automation (manufacturing without the aid of human thinking) is the advanced stage of mechanisation.

Technological Innovation

- Technological innovations through research and development strategy are an important aspect of modern manufacturing for quality control, eliminating waste and inefficiency, and combating pollution.

Organisational Structure and Stratification

- Modern manufacturing is characterised by:

- a complex machine technology

- extreme specialisation and division of labour for producing more goods with less effort, and low costs

- vast capital

- large organisations

- executive bureaucracy.

Classification of Manufacturing Industries

Industries based on Size

- The amount of capital invested, number of employees, and volume of production determine the size of industry.

- Accordingly, industries may be classified into household or cottage, small-scale and large-scale.

Household industries or cottage manufacturing

- It is the smallest manufacturing unit.

- The artisans use local raw materials and simple tools to produce everyday goods in their homes with the help of their family members or part-time labour.

- Finished products may be for consumption in the same household or, for sale in local markets.

- Some common everyday products produced in this sector of manufacturing include foodstuffs, fabrics, mats, tools, furniture, leather, pottery, bricks from clays, etc.

- Goldsmiths make jewellery of gold, silver and bronze.

Small Scale Manufacturing

- Small scale manufacturing is distinguished from household industries by its production techniques and place of manufacture (a workshop outside the home/cottage of the producer).

- This type of manufacturing uses local raw material, simple power-driven machines and semi-skilled labour.

- It provides employment and raises local purchasing power.

- Therefore, countries like India, China, Indonesia and Brazil, etc. have developed labour-intensive small scale manufacturing in order to provide employment to their population.

Large Scale Manufacturing

- Large scale manufacturing involves a large market, various raw materials, enormous energy, specialised workers, advanced technology, assembly-line mass production and large capital.

- This kind of manufacturing developed in the last 200 years, in the United Kingdom, north-eastern U.S.A. and Europe. Now it has diffused to almost all over the world.

- On the basis of the system of large scale manufacturing, the world’s major industrial regions may be grouped under two broad types, namely

- traditional large-scale industrial regions which are thickly clustered in a few more developed countries.

- high-technology large scale industrial regions which have diffused to less developed countries.

Industries based on Inputs/Raw Materials

- On the basis of the raw materials used, the industries are classified as: (a) agro-based; (b) mineral based; (c) chemical-based; (d) forest-based: and (e) animal-based.

- Major agro-processing industries are food processing, sugar, pickles, fruits juices, beverages (tea, coffee and cocoa), spices and oils fats and textiles (cotton, jute, silk), rubber, etc.

- Agro-processing includes canning, producing cream, fruit processing and confectionery.

- Timber for the furniture industry, wood, bamboo and grass for the paper industry, lac for lac industries come from forests.

- Leather for the leather industry and wool for woollen textiles are obtained from animals.

Industries Based on Output/Product

- The industries whose products are used as raw material to make other goods are called basic industries.

- E.g. Iron and steel, copper smelting and aluminium smelting industries.

- The consumer goods industries produced goods which are consumed by consumers directly.

- E.g. industries producing bread, tea, soaps, paper, etc. are consumer goods or non-basic industries.

Foot Loose Industries

- Foot loose industries can be located in a wide variety of places.

- They are not dependent on any specific raw material, weight losing or otherwise.

- They largely depend on component parts which can be obtained anywhere.

- They produce in small quantity and also employ a small labour force.

- These are generally not polluting industries.

- The essential factor in their location is accessibility by road network.

Traditional Large-Scale Industrial Regions

- These are based on heavy industry, often located near coal-fields and engaged in metal smelting, heavy engineering, chemical manufacture or textile production.

- These industries are now known as smokestack industries.

- Traditional industrial regions can be recognised by:

- High proportion of employment in manufacturing industry.

- High-density housing, often of inferior type, and poor services.

- Unattractive environment, for example, pollution, waste heaps, and so on.

- Problems of unemployment, emigration and derelict land areas caused by closure of factories because of a worldwide fall in demand.

Concept of High Technology Industry

- High technology, or simply high-tech, is the latest generation of manufacturing activities.

- It is best understood as the application of intensive research and development (R and D) efforts leading to the manufacture of products of an advanced scientific and engineering character.

- Professional (white-collar) specialists greatly outnumber the actual production (blue-collar) workers.

- Robotics on the assembly line, computer-aided design (CAD) and manufacturing, electronic controls of smelting and refining processes, etc. are notable examples of high-tech industry.

- Neatly spaced, low, modern, dispersed, office-plant-lab buildings rather than massive assembly structures, factories and storage areas mark the high-tech industrial landscape.

- Planned business parks for high-tech start-ups have become part of regional development schemes.

- High-tech industries which are regionally concentrated, self-sustained and highly specialised are called technopolies.

- The Silicon Valley near San Francisco and Silicon Forest near Seattle are examples of technopolies.

Tertiary Activities

- Tertiary activities involve the commercial output of services rather than the production of tangible goods.

- They are not directly involved in the processing of physical raw materials.

- Common examples are the work of a plumber, electrician, technician, launderer, barber, shopkeeper, driver, cashier, teacher, doctor, lawyer and publisher etc.

- Tertiary activities include both production and exchange.

- The production involves the ‘provision’ of services that are ‘consumed’.

- The output is indirectly measured in terms of wages and salaries.

- The exchange involves trade, transport and communication facilities that are used to overcome distance.

Types of tertiary activities

Transportation

- World’s resources are not equitably distributed across regions, and no region is self-sufficient.

- This makes the exchange (transport) of resources, goods and services a necessity throughout the world.

- The areas of shortage are supplied by areas of surplus (bringing sources of supply and demand together) by a wide network of transport systems.

- The most determining factor for the exchange of resources and goods other than supply and demand is the economic distance.

Economic distance

- Economic distance is the maximum distance a resource or a good can be transported such that the increase in the value of the transported good is higher than the cost of transportation.

- The maximum economic distance is determined by the origin and destination (distance), demand and supply, nature of the good ― weight, size, fragility, perishability, etc. and other factors like terrain, infrastructure, mode of transport, competition, costs (fuel, wages, transport, insurance), feasibility, etc.

- For example, the maximum economic distance of a perishable product like milk is much lesser compared to that of iron.

- Milk can be transported for a longer distance using refrigeration; however, the cost of refrigeration (operating cost involved in the movement of good) seriously limits the economic distance.

- The economic distance of large quantities of petroleum can be increased by transporting it through pipelines rather than tankers.

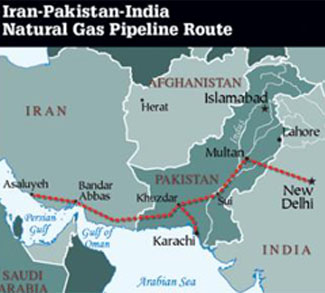

- However, India imports petroleum from Iraq and Iran by oil tankers as laying a pipeline through Pakistan is currently not feasible.

- Likewise, India is not able to import gas from Russia as the gas pipeline needs to pass through China.

The cost structure of different methods of transport

- In selecting the mode of transport, distance, in terms of time or cost, is the determining factor.

- Isochrone lines are drawn on a map to join places equal in terms of the time taken to reach them.

- Transport of goods involve various kinds of costs such as line-haul costs (cost of movement: fuel, wages) overhead costs (costs of terminal facilities – loading and unloading, vehicles, equipment, roads, railway tracks, maintenance, etc.) and transfer costs (indirect costs such as insurance cover, taxes, etc.)

- Line-haul and overhead costs differ between various methods of transport.

- The overhead costs of ocean transport (ports, terminals) are high when compared to that of road transport.

- However, the line-haul costs of road transport rise rapidly with distance compared to that of ocean transport as the costs of ocean transport are spread over much larger cargo.

- Rail transport occupies an intermediate position in terms of both line-haul and overhead costs.

- Road transport is, therefore, cheapest over short distances, rail over medium distances (D1-D2) and ocean transport over long distances (beyond D2).

Tourism

- Improvements in the standard of living and increased leisure time has promoted tourism.

- It has become the world’s single largest tertiary activity in total registered jobs (250 million) and total revenue (40 per cent of the total GDP).

- Tourism fosters the growth of infrastructure industries, retail trading, and craft industries (souvenirs).

- The warmer places around the Mediterranean Coast and the West Coast of India are some of the popular tourist destinations in the world.

- Most people from colder regions expect to have warm, sunny weather for beach holidays. This is one of the main reasons for the importance of tourism in Southern Europe and the Mediterranean lands.

- The Mediterranean climate offers almost consistently higher temperatures than in other parts of Europe, long hours of sunshine and low rainfall throughout the peak holiday season.

- Home-stay has emerged as a profitable business such as heritage homes in Goa, Madikere and Coorg in Karnataka.

Medical Tourism

- When medical treatment is combined with international tourism activity, it lends itself to what is commonly known as medical tourism.

- India has emerged as the leading country of medical tourism in the world.

- World class hospitals located in metropolitan cities cater to patients all over the world.

Quaternary Activities

- Quaternary activities are a segment of the service sector that is knowledge oriented.

- This sector can be divided into quaternary and quinary activities.

- Quaternary activities involve some of the following: the collection, production and dissemination of information or even the production of information.

- Quaternary activities centre around research, development and may be seen as an advanced form of services involving specialised knowledge and technical skills.

The Quaternary Sector

- Over half of all workers in developed economies are in the ‘Knowledge Sector’.

- Personnel working in elementary schools and university classrooms, hospitals and doctors’ offices, theatres, accounting and brokerage firms all belong to this category of services.

- Like some of the tertiary functions, quaternary activities can also be outsourced.

Quinary Activities

- The highest level of decision-makers or policymakers perform quinary activities.

- Quinary activities are services that focus on the creation, re-arrangement and interpretation of new and existing ideas, data interpretation and the use and evaluation of new technologies.

- Often referred to as ‘gold collar’ professions, they represent exclusive and highly paid senior business executives, government officials, research scientists, financial and legal consultants, etc.

Outsourcing

- Outsourcing is giving work to an outside agency to improve efficiency and to reduce costs.

- When outsourcing involves transferring work to overseas locations, it is described by the term offshoring.

- Business activities that are outsourced include information technology (IT), human resources, customer support and call centre services and at times, also manufacturing and engineering.

- Data processing is an IT related service easily be carried out in Asian, East European and African countries.

- In these countries, IT skilled staff with excellent English language skills are available at lower wages than those in developed countries.

- Thus, a company in Hyderabad does work on a project based on GIS techniques for a country like the U.S.A.

- Overhead costs are also much lower, making it profitable to get job-work carried out overseas, whether it is in India, China or even a less populous country like Botswana in Africa.

- Outsourcing countries are facing resistance from job-seeking youths in their respective countries.

- The comparative advantage is the main reason for continuing outsourcing.

- New trends in quinary services include knowledge processing outsourcing (KPO) and ‘home shoring’, the latter as an alternative to outsourcing.

- The KPO industry is distinct from Business Process Outsourcing (BPO) as it involves highly skilled workers.

- KPO enables companies to create additional business opportunities.

- Examples of KPOs include research and development (R and D) activities, e-learning, business research, intellectual property (IP) research, the legal profession and the banking sector.

Some of the factors influencing locations of various sectors (industries)

- Location of industries is influenced by several factors like access to raw materials, power, market, capital, transport and labour, etc.

- Relative significance of these factors varies with time and place.

- There is a strong relationship between raw material and type of industry.

- It is economical to locate the manufacturing industries at a place where the cost of production and delivery cost of manufactured goods to consumers are the least.

- Transport costs, to a great extent, depend on the nature of raw materials and manufactured products.

- Major concentrations of modern manufacturing have flourished in a few number of places.

- These cover less than 10 per cent of the world’s land area.

Historical Factors

- The colonial past greatly influenced industrial nodes such as Mumbai, Kolkata and Chennai.

- During the initial phase of colonisation, manufacturing received impetus provided by the European traders.

- Surat, Vadodara, Kozhikode, Coimbatore, Mysuru, etc., emerged as important manufacturing centres.

- In the subsequent industrial phase of colonialism, these manufacturing centres experienced rapid growth due to competition from imported British goods and the discriminatory policies of the colonial power.

- In the last phase of colonialism, the British promoted few industries in selected areas.

- This led to broader spatial coverage by different types of industries in the country.

Access to Raw Materials

- The raw material used by industries should be cheap and easy to transport.

- Industries based on cheap, bulky and weight-losing material (ores) are located close to the sources of raw material. E.g. steel, sugar, pulp, copper smelting and cement industries.

- This is why most of the iron and steel industries are located either near coalfields (Bokaro, Durgapur, etc.) or near sources of iron ore (Bhadravathi, Bhilai, and Rourkela).

- Agro-processing and dairy products are processed close to the sources of farm produce or milk supply (perishables), respectively.

Access to energy sources

- Industries which use more power are located close to the source of the energy supply. E.g. aluminium industry, synthetic nitrogen manufacturing industry, etc.

- Earlier coal was the main source of energy; today, hydroelectricity and petroleum are also important sources of energy for many industries.

Access to Market

- The existence of a market for manufactured goods is the most critical factor in the location of industries.

- The developed regions of Europe, North America, Japan and Australia provide large global markets as the purchasing power of the people is very high.

- The densely populated regions of South and South-east Asia also provide large markets.

- Some industries, such as aircraft manufacturing, defence industry, have a global market.

- The cotton textile industry uses a non-weight-losing raw material and is generally located in a large urban centre, e.g. Mumbai, Ahmedabad, Surat, etc.

- Petroleum refineries are also located near the markets as the transport of crude oil is easier, and several products derived from them are used as raw materials in other industries.

- Koyali, Mathura and Barauni refineries are typical examples.

Access to Transportation and Communication Facilities

- The cost of transport plays an important role in the location of industrial units.

- The industries shifted to interior locations, only when railway lines were laid.

- Western Europe and eastern North America have a highly developed transport system which has always induced the concentration of industries in these areas.

- The concentration of industries in Mumbai, Chennai, Delhi and in and around Kolkata was due to the fact that they initially became the nodal point having transport links.

Supply of cheap labour and skilled workforce

- Some types of manufacturing still require skilled labour.

- In India, labour is quite mobile and is available in large numbers due to our large population.

- Increasing mechanisation, automation and flexibility of industrial processes have reduced the dependence of industry upon the labours.

- However, the importance of a skilled workforce in the quaternary sector is only increasing day by day.

- Technopolies such as Silicon Valley (San Francisco) are highly dependent on skilled IT professionals.

Access to Agglomeration Economies/Links between Industries

- Many industries benefit from nearness to leader-industry and other industries.

- These benefits are termed as agglomeration economies.

- Savings are derived from the linkages which exist between different industries.

- These factors operate together to determine industrial location.

Industrial inertia

- Industrial inertia is when a firm remains in its original location even after the initial advantage or alluring factors that led to them locating there has disappeared.

- Reasons behind industrial inertia:

- there may be strong transportation and economic linkage with other activities of the area.

- irreplaceable skilled labour force.

- cost and disruption that can arise from relocation.

- encouraging government policy like subsidies, ease of doing business, etc.

- Sometimes it is easier to modernize an existing location rather than relocation. E.g. when the cotton industry declined in the U.K., the textile mills were converted into light engineering goods factories.

Government Policy

- Governments adopt ‘regional policies’ to promote ‘balanced’ economic development and hence set up industries in particular areas.

- Establishment of iron and steel industry in Bhilai and Rourkela were based on decision to develop backward tribal areas of the country.

- At present, the government of India provides lots of incentives to industries locating in backward areas.

Questions

- In which one of the following countries, co-operative farming was the most successful experiment? (a) Russia (b) Denmark (c) India (d) The Netherlands

- Growing of flowers is called: (a) Truck farming (c) Mixed farming (b) Factory farming (d) Floriculture

- Which one of the following types of cultivation was developed by European colonists? (a) Kolkoz (b) Viticulture (c) Mixed farming (d) Plantation

- In which one of the following regions is extensive commercial grain cultivation not practised? (a) American Canadian prairies (b) European Steppes (c) Pampas of Argentina (d) Amazon Basin

- In which of the following types of agriculture is the farming of citrus fruit very important? (a) Market gardening (b) Plantation agriculture (c) Mediterranean agriculture (d) Co-operative farming

- Which one type of agriculture amongst the following is also called ‘slash and burn agriculture’? (a) Extensive subsistence agriculture (b) Primitive subsistence agriculture (c) Extensive commercial grain cultivation

- Which one of the following does not follow monoculture? (a) Dairy farming (c) Plantation agriculture (b) Mixed farming (d) Commercial grain farming

- Which one of the following statements is wrong?

- Cheap water transport has facilitated the jute mill industry along the Hugli.

- Sugar, cotton textiles and vegetable oils are footloose industries.

- The development of hydro-electricity and petroleum reduced, to a great extent, the importance of coal energy as a locational factor for industry.

- Port towns in India have attracted industries.

- In which one of the following types of economy are the factors of production owned individually? (a) Capitalist (b) Mixed (c) Socialist (d) None

- Which one of the following types of industries produces raw materials for other industries? (a) Cottage Industries (b) Small-scale Industries (c) Basic Industries (d) Footloose Industries

- Which one of the following pairs is correctly matched? (a) Automobile industry … Los Angeles (b) Shipbuilding industry … Lusaka (c) Aircraft industry … Florence (d) Iron and Steel industry … Pittsburgh

- Discuss the major trends of modern industrial activities especially in the developed countries of the world.

- Explain why high-tech industries in many countries are being attracted to the peripheral areas of major metropolitan centres.

- Africa has immense natural resources and yet it is industrially the most backward continent. Comment.

- Which one of the following is a tertiary activity? (a) Farming (b) Trading (c) Weaving (d) Hunting

- Which one of the following activities is NOT a secondary sector activity? (a) Iron Smelting (b) Catching fish (c) Making garments (d) Basket Weaving

- Which one of the following sectors provides most of the employment in Delhi, Mumbai, Chennai and Kolkata? (a) Primary (b) Quaternary (c) Secondary (d) Service

- Jobs that involve high degrees and level of innovations are known as: (a) Secondary activities (b) Quaternary activities (c) Quinary activities (d) Primary activities

- Which one of the following activities is related to the quaternary sector? (a) Manufacturing computers (b) Paper and Raw pulp production (c) University teaching (d) Printing books

- Which one out of the following statements is not true?

- Outsourcing reduces costs and increases efficiency.

- At times engineering and manufacturing jobs can also be outsourced.

- BPOs have better business opportunities as compared to KPOs.

- There may be dissatisfaction among job seekers in the countries that outsource the job.

Iron and Steel Industry

- The iron and steel industry forms the base of all other industries and, therefore, it is called a basic industry.

- It may also be called a heavy industry because it uses large quantities of bulky inputs and outputs.

- Iron is extracted from iron ore by smelting (heating, melting & separation of impurities) in a blast furnace with carbon (coke) and limestone.

- The molten iron is cooled and moulded to form pig iron.

- The pig iron is used for converting into steel by adding strengthening materials like manganese.

Factors that influence the location of Iron and Steel Industry

Raw Material

- The essential bulk inputs of iron & steel industry are iron ore (gross/weight-losing raw material), fuel (coal; weight-losing), limestone (flux) & water (required for cooling & worker safety).

- These bulk inputs, especially iron ore and coal, have a significant influence on the location of the industry.

- Other raw material like dolomite (refractory material), manganese, chromite (stainless steel making) are required only in small quantities.

Charcoal: Primitive iron ore smelters near forests

- All iron-making blast furnaces were fuelled by charcoal until the end of the seventeenth century.

- The industry remained primitive as 10-15 tonnes of charcoal was needed to smelt one tonne of iron.

- The steam engine was not yet invented (to bulk transport coal, iron ore) and hence fuel and power were immobile.

- Hence the iron smelting had to be carried out close to the forests (charcoal).

- Till recently, Vishweshvaraiah Iron and Steel Plant in Karnataka relied on charcoal as fuel.

Visvesvaraiya Iron and Steel Works Ltd. (VISL)

- It is the third integrated steel plant in India.

- It was initially called the Mysore Iron and Steel Works.

- It is located close to an iron ore producing area of Kemangundi in the Bababudan hills.

- Limestone and manganese are also locally available.

- But this region has no coal.

- In the beginning, charcoal obtained by burning wood from nearby forests was used as fuel till 1951.

- Afterwards, electric furnaces which use hydroelectricity from the Jog Falls (Sharavati) hydel power project were installed.

- The Bhadravathi river supplies water to the plant.

Coal and iron ore: Near Coalfields during the Industrial Revolution

- With the advent of the steam engine and railways and the successive industrial revolution (the 1760s) in the eighteenth century, the iron and steel industry developed on a massive scale in the regions where coal and iron ore were available in close proximity.

- Processing one tonne of iron ore required 8-12 tonnes of coal (for smelting and transportation), which meant that it was cost-effective to have an iron and steel plant near a coalfield rather than at an iron mine.

- E.g. Iron industry in Western Europe and North-Eastern USA

- Ruhr Valley in Germany.

- Lancashire, York shire and South Wales in Britain.

- Appalachian-Pennsylvania-Great Lakes region in United States.

- New South Wales region in Australia.

- Wuhan, Anshan, Chongqing in China.

- A large network of canals was established to supply water to the industry.

- Canals not only supplied water but also offered a cheap mode of transportation for transporting raw materials and finished goods.

Coal and Iron ore: Regions with close proximity to Coalfields and Iron Ore mines

- Birmingham District in Alabama became the largest iron and steel producer in the southern United States due to the close proximity of abundant deposits of iron ore, coal, limestone, and dolomite.

- In India, there is a crescent-shaped region comprising parts of Chhattisgarh, Northern Odisha, Jharkhand and western West Bengal, which is extremely rich in high-grade iron ore, good quality coking coal and other supplementing raw materials.

- Here the iron and steel industry consists of large integrated steel plants.

Image Source: NROER

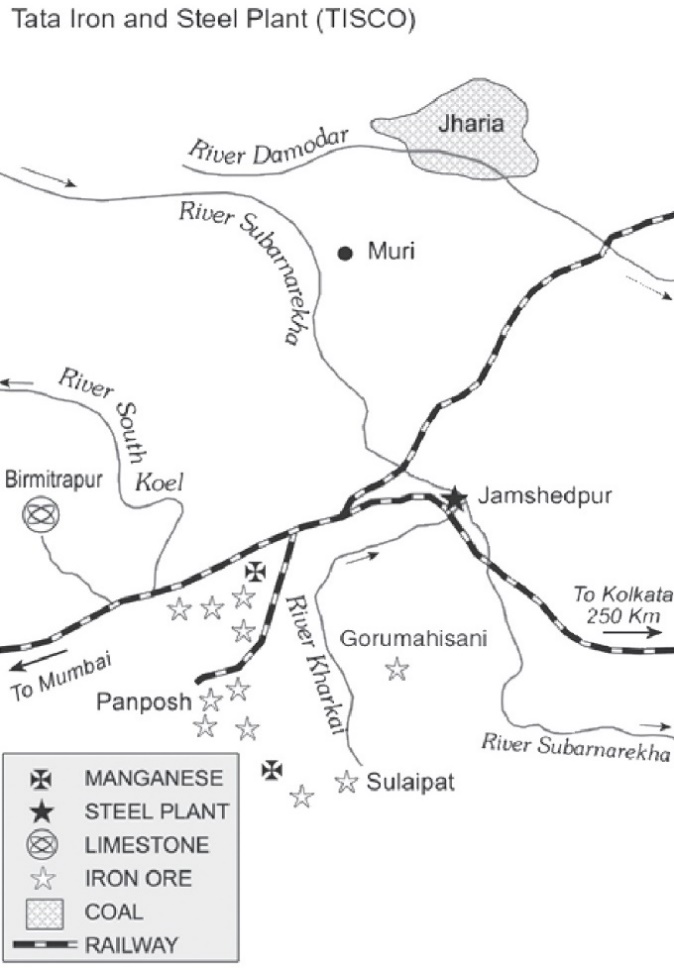

TISCO

- The Tata Iron and Steel plant lies very close to the Mumbai-Kolkata railway line and about 240 km away from Kolkata, which is the nearest port for the export of steel.

- The rivers Subarnarekha and Kharkai provide water to the plant.

- The iron ore for the plant is obtained from Noamundi, and Badam Pahar and coal is brought from Joda mines in Odisha.

- Coking coal comes from Jharia and west Bokaro coalfields.

IISCO

- The Indian Iron and Steel Company (IISCO) set up its first factory at Hirapur (Madhya Pradesh) and later at Kulti and Burnpur (West Bengal).

- All the three plants are located very close to Damodar valley coal fields (Raniganj, Jharia, and Ramgarh).

- Iron ore comes from Singhbhum in Jharkhand.

- Water is obtained from the Barakar River, a tributary of the Damodar.

- All the plants are located along the Kolkata-Asansol railway line.

Rourkela Steel Plant

- After independence, during the Second Five Year Plan (1956-61), three new integrated steel plants were set up with foreign collaboration: Rourkela in Odisha, Bhilai in Chhattisgarh and Durgapur in West Bengal.

- In 1973, the Steel Authority of India Limited (SAIL) was created to manage these plants.

- The Rourkela Steel plant was set up in the Sundargarh district of Odisha in collaboration with Germany.

- This plant has a unique locational advantage, as it receives coal from Jharia (Jharkhand) and iron ore from Sundargarh and Kendujhar.

- The Hirakud project supplies power for the electric furnaces and water is obtained from the Koel and Sankh rivers.

Bhilai Steel Plant

- The Bhilai Steel Plant was established with Russian collaboration in Durg district of Chhattisgarh.

- Iron ore comes from Dalli-Rajhara mine and coal from Korba and Kargali coal fields.

- Water comes from the Tanduladam and the power from the Korba Thermal Power Station.

- This plant also lies on the Kolkata-Mumbai railway route.

- The bulk of the steel produced goes to the Hindustan Shipyard at Vishakhapatnam.

Durgapur Steel Plant

- Durgapur Steel Plant in West Bengal was set up in collaboration with the government of UK.

- This plant lies in Raniganj and Jharia coal belt and gets iron ore from Noamundi.

- Durgapur lies on the main Kolkata-Delhi railway route.

- Hydel power and water are obtained from the Damodar Valley Corporation (DVC).

Coking coal shortage

- Sweden has high-grade iron ore but doesn’t have enough cocking coal.

- Hence it specializes in non-ferrous metallurgy and light engineering rather than iron-steel industry.

- Sweden exports its iron ore to Ruhr (Germany) and imports pig iron from Ruhr.

- It converts pig iron into steel, using electrical furnaces. (Sweden has abundant hydropower potential ― hydropower contributes to more than half of energy production).

- The steel thus manufactured, is used for making high-value items.

Transportation: Near coastal areas for cheaper raw material imports

- With the beginning of the 20th century, colonial powers like Japan, with no significant iron ore or coal resource base, began to set up iron and steel plants near the ports. E.g. steel industry in Osaka-Kobe.

- Also, as the coal reserves started depleting in Western Europe and North-Eastern USA, a part of the industry, which relied on imported coal, began to relocate to port cities.

- In the USA, the industry cropped up in the coastal cities of Buffalo, Cleveland, Detroit, Chicago that used imported coal from Canada (through Saint Lawrence Seaway) and Appalachian coalfields.

- In India too, steel plants were set up at Vishakhapatnam, Ratnagiri and Mangalore.

The Ruhr, Germany

- Ruhr has been one of the major industrial regions of Europe for a long time.

- Coal and iron and steel formed the basis of the economy.

- But after the 1950s, the demand for coal declined (due to competition from cheaper imported coal and oil), and the iron ore was also exhausted.

- However, the iron and steel industry thrived using imported ore brought by Rhine River waterway to the Ruhr from deeper water ports such as Rotterdam (Netherlands).

- The Ruhr region is responsible for 80 per cent of Germany’s total steel production.

- The future prosperity of the Ruhr is based less on coal and iron ore and more on the automobile industry.

Transport Cost Minimization

Bokaro-Rourkela combine

- Bokaro Steel Plant steel plant was set up in 1964 at Bokaro with Russian collaboration.

- This plant was set up on the principle of cost minimisation by creating Bokaro-Rourkela combine.

- It receives iron ore from the Rourkela region and the wagons on return take coal to Rourkela.

- Other raw materials come to Bokaro from within a radius of about 350 km.

- The Damodar Valley Corporation supplies water and hydel power.

Ural-Kuznetsk combine

- The Ural-Kuznetsk industrial combine was formed in the early 1930s.

- It became a centre for the production of iron and steel with raw materials and finished products being shipped to and from sites in the Kuzbas and Urals.

- The Ural of Russia is rich in iron ore deposits.

- Kuznetsk Basin in Western Siberia is rich in coal deposits.

- Coal from Kuznetsk Basin is sent to the Ural region by Railways.

- The returning wagons after emptying coal, bring iron ore from the Ural region.

Access to markets: Mini Steel plants

- The large integrated steel industry is traditionally located close to the sources of raw materials – iron ore, coal, manganese and limestone – or at places where these could be easily brought, e.g. near ports.

- But in mini steel mills with electric furnaces, access to markets is more important than inputs.

- These are less expensive to build and operate and can be located near markets because of the abundance of scrap metal, which is the primary input.

- Traditionally, most of the steel was produced at large integrated plants, but mini mills are limited to just one-step process – steelmaking – and are gaining ground.

Economies of Linkages and Agglomerations: Duluth-Detroit-Cleveland-Pittsburgh

- Lake Superior region of Michigan has significant iron ore deposits but has no coal or markets nearby.

- The only profitable way to exploit the ore was to transport it in bulk to distant blast furnaces on the lower Great Lakes — to places like Cleveland and Chicago.

- On the other hand, Pittsburgh’s (Pennsylvania) iron and steel industry was facing a shortage of local iron ore but had abundant coal reserves.

- Hence Pittsburgh started importing iron ore from the Lake Superior region of Michigan and Minnesota and started exporting coal to Duluth in Minnesota (Lake Superior region).

- Ships brought iron ore from Lake Superior region to Cleveland while the railway wagons brought coal from Pittsburgh.

- On their return journey, ships carried coal to Lake Superior region whereas railway wagons brought iron ore to Pittsburgh.

- Cleveland, which is located at the crossroads (on the banks of Lake Erie), got coal from Pittsburgh and iron ore from Lake Superior region of Michigan.

- Thus, despite having neither of the resources locally, the region around Cleveland has a thriving iron and steel industry.

- The same is the case with Chicago in Illinois, Detroit in Michigan and Buffalo in New York.

Competition

- In the latter half of the twentieth century, industrial west’s iron and steel industry began a decline.

- This is due to the fall in local demand, reduced exports, overcapacity and saturation, outdated technology, rise in mini scrap steel mills, rise in wages, and the emergence of China as the major steel producer.

- Some areas affected by the steel crisis were the Rust belt in North America, the English Midlands in the United Kingdom, the Ruhr area in West Germany and Bergslagen in Sweden.

- Other major steel-producing cities, such as Chicago, Gary, East Chicago, Cleveland, Toledo, and Pittsburgh, never recovered from the losses in the industry.

- The causes of the declines in these countries were similar to the United Kingdom’s: foreign competition (primarily against each other), overcapacity resulting from the construction of mills during the post-war boom and integration of markets, and productivity gains.

- China’s steel production went from a third of the output of American mills in 1981 to match US production only 12 years later.

- Today China’s steel industry produces roughly half the steel in the world.

Technology

- A rise in simpler basic oxygen furnace (BOF) and the recycling of scrap, led to the decline and consolidation of the industry in the 1970s and 1980s across the industrial west.

- This further reduced coal requirement and the new industry could move away from coalfields.

Quality of ore, economies of scale, Cheap labour

- China is the leading producer and consumer of iron and steel in the world.

- But most of the Chinese iron and steel industry depends on imported iron ore from Australia, Brazil and imported cocking coal from Australia and Indonesia.

- This is because of the poor quality of both iron ore and coal in China.

- Despite the raw material imports, Chinese steel is highly competitive in the global markets due to the ‘economies of scale’ production and cheap labour.

Industrial Inertia

- Though alternate sources of energy are available, traditional industries are still located around the coalfields, sometimes even after the coal mines have exhausted.

- Example Ruhr in Germany, Pittsburgh in USA and Lancashire in the UK.

- Possible reasons behind industrial inertia in the iron and steel industry:

- The biggest reason for industrial inertia is the high overhead costs and regulatory clearances associated with the relocation of the heavy industry.

- Industries will simply stay put as long as the cost of transportation of raw materials is well below the cost of relocation.

- Moreover, transportation cost has fallen drastically. Countries like China have been able to import iron ore from as far as Goa and still produce steel globally competitive prices.

- Well established economic (allied sectors like automobile, heavy engineering and markets) and transport linkages are already available in the present locations and the new areas if remote will offset the locational advantages like availability of raw materials.

- Industries present for decades would have established a very efficient supply chain and markets. There is always a risk of relocation benefitting the competitor more.

- Areas near coalfields developed into industrial cities with a large pool of skilled workforce. New area may not have the same labour supply (not a significant reason in India due to the unemployment rate).

- Economies of agglomeration offer a high bargaining chip (social, political and economic). Relocation may spell trouble in times of adverse government policies.

- For example, to protect down sliding Pittsburgh steel industry, the US government made steel-pricing policies in the early 1900s such that no other competing region could sell steel at prices lower than the prices at which Pittsburgh industry sold its steel.

Rules and regulations

- POSCO India is an Indian subsidiary of Korean iron and steel conglomerate POSCO.

- POSCO signed a memorandum of understanding in 2005 with Odisha to construct a $12 billion steel plant

- The land acquisition process was not fructified due to the tussle between the Environment Ministry (Forests Rights Act), the state government, local dwellers and the Supreme Court.

- Apart from Odisha, POSCO India withdrew from project sites in Karnataka and Maharashtra states due to similar issues.

Strategic reasons

- During WWII, the allied powers had to pay a heavy price for concentrating all their industries in a few pockets. It made it easy for the enemy aerial bombers to target these concentrated industrial pockets.

- After WWII, the US government decided to diversify its industrial base, and some steel plants were set up in the west ― far away from the highly concentrated industrial East (Great Lakes-Pittsburgh region).

- Similarity, USSR adopted a policy to disperse Soviet industries on the Eastern side, towards the Pacific coast ― far away from the Ukraine-Donbas region.

Government policies

- Establishment of iron and steel industry in Bhilai and Rourkela were based on the decision to develop backward tribal areas of the country.

- Three new steel plants set up in the Fourth Plan period are away from the primary raw material sources.

- All three plants are located in South India: The Vizag Steel Plant, Vijayanagar Steel Plant at Hospet in Karnataka (now it uses local iron ore and limestone) and the Salem Steel Plant in Tamil Nadu.

- Salem steel plant was set up due to the insistence of the then TN Chief Minister M. Karunanidhi. It had neither of the raw materials nearby.

- In China, backyard furnaces were constructed to further the Great Leap Forward ideology of Mao for rapid industrialization of China.

- However, the backyard furnaces produced high-carbon pig iron, which needs to be smelted further to make steel. Hence, almost all of the iron produced by backyard furnaces was practically useless.

Distribution of Iron and Steel Industry

- The industry is one of the most complex and capital-intensive industries and is concentrated in the advanced countries of North America, Europe and Asia.

- In the U.S.A, most of the production comes from the Appalachian region (Pittsburgh), Great Lake region (Chicago, Erie, Cleveland, Lorain, Buffalo and Duluth) and the Atlantic Coast (Sparrows Point & Morrisville).

- The industry has also moved towards the southern state of Alabama (Birmingham).

- Pittsburgh area is now losing ground. It has now become the “rust bowl” of U.S.A.

- In Europe, the U.K., Germany, France, Belgium, Netherlands & Russia are the leading producers.

- The vital steel centres are

- Scun Thorpe, Port Talbot, Birmingham and Sheffield in the U.K.;

- Duisburg, Dortmund, Dusseldorf and Essen in Germany;

- Le Creusot and St. Ettienne in France; and

- Moscow, St. Petersburgh, Lipetsk, Tula, in Russia and

- Krivoi Rog, and Donetsk in Ukraine.

- In Asia, the important centres include

- Nagasaki and Tokyo-Yokohama in Japan;

- Shanghai, Tienstin and Wuhan in China; and

- Jamshedpur, Kulti-Burnpur, Durgapur, Rourkela, Bhilai, Bokaro, Salem, Visakhapatnam and Bhadravati in India.

- At 51.3%, China is the world’s largest producer of steel.

- India has overtaken Japan to become the second-largest producer of steel.

- India’s steel production in 2018-19 stood at 111 million tonnes.

- The construction industry is the largest consumer of steel in India.

- The National Steel Policy, 2017, has envisaged 300 million tonnes of production capacity by 2030-31.

Cotton Textile Industry

(This topic is important for ‘Modern World History: Industrial Revolution’ also)

- A cotton mill houses spinning or weaving machinery for the production of yarn or cloth from cotton.

- Till the industrial revolution, cotton cloth was made using hand-spinning techniques (wheels) and looms.

- In 18th century, power looms facilitated the development of cotton textile industry, first in Britain and later in other parts of the world.

- In India, the cotton textiles industry is the single largest organised industry.

- Being labour intensive at all stages, it employs a large number of people.

Factors that affect the location of the cotton textile industry

| Raw material |

|

| Transportation linkages |

|

| Access to market for the cotton textiles |

|

| Access to market for the byproducts of cotton textile industry |

|

| Power |

|

| Climate |

|

| Labour |

|

| Water |

|

| Government interventions |

|

| Technological developments |

|

Cotton Textile Manufacturing Regions of the World

Cotton Textile Manufacturing Regions of the World

Cotton Textile Manufacturing Regions of the World

Factors responsible for the Localization of the British Cotton Textile Industry

| Raw material |

|

| Capital |

|

| Connectivity and Transportation |

|

| Market |

|

| Power & Water |

|

| Technology (Inventions and Innovations) |

|

| Climate |

|

| Labour |

|

Factors that led to the decline of the British Textile Industry

| Loss of Raw material |

|

| Loss of Market |

|

| Competition from the U.S. |

|

| Interwar period and competition from Japan |

|

| Cheap electricity |

|

| Higher labour wages and Rise of China and India |

|

How the British destroyed the Egyptian Cotton Textile Industry

- Muhammed Ali (founder of modern Egypt) embraced cotton as a valuable cash crop.

- The Nile Delta provided the most ideal conditions for the cultivation of extra-long-staple (Pima) cotton.

- Muhammad Ali established cotton textile industry in an effort to compete with the European industries.

- In the 1850s, Egypt had become the first country outside Europe or the United States to have a railway line.

- With the decline in imports from the U.S., the British were desperately looking for new cotton markets.

- First, the British financed projects in Egypt, and when Egypt defaulted, grabbed its cotton industry (in typical British style). The demise of the Egyptian cotton textile industry was as quick as its rise.

- The British made full use of Nile’s fertility to feed their cotton industry.

- Nowadays, very little of the celebrated long-staple cotton is grown in the Nile Delta (whose fertility greatly decreased due to overexploitation and construction of the Aswan Dam ― reduced silt replenishment).

- China, with its cheap cotton exports, destroyed whatever was left.

Commercial Species of Cotton

|

Factors responsible for the Localization of the American Cotton Textile Industry

- The climate of Southern U.S. (hot, humid & 200 frost-free days) is the best for cotton cultivation.

- In the Cotton Belt (South-eastern U.S.), cotton was the predominant cash crop from the late 18th century into the 20th century.

- In the 1890s to 1950s, the boll weevil, a pest from Mexico, began to spread across the United States, affecting yields drastically as it moved east.

- The boll weevil pest, soil depletion and cultivation of corn, wheat and soybeans led to the westward migration of the Cotton Belt.

- The commercial cultivation of cotton is now concentrated only in the most favourable areas which are the Mississippi flood plains, Atlantic coastlands and Northern Texas.

- More than 99% of the cotton grown in the U.S. is of the upland variety, with the rest being American Pima.

- The major markets for the upland U.S. cotton (Gossypium hirsutum ― short-staple) are Vietnam, China, Turkey, Pakistan, India, Indonesia, Bangladesh, Mexico, Thailand etc.

- High-quality cotton (American Pima) produced in California, Arizona, and New Mexico is exported to mills in Japan, Korea, and Europe for use in the production of high-quality textile products.

The U.S. Cotton Textile Industry

- The invention of Cotton Gin in 1793 enabled the rapid growth of cotton industry in New England (it consists of six states in the north-eastern corner of U.S. Boston is the most important city).

- Strong banking industry (New York is only 350 km from Boston), British immigrants, domination in the cotton trade and coalfields nearby (Appalachian Region) gave it an edge over the American South.

- By 1860, Boston and New York (both port cities) played a dominant role in the cotton trade.

- When the Civil War began in 1861, the cotton exports from the American South to Britain stopped.

- This gave impetuous to the U.S. cotton textile industry.

- Other industries became prominent in New England and the cotton industry was running out of space.

- Migration of the textile industry from New England to the American South started in the 1920s.

- Lower taxes, plentiful labour supplies, adequate water, and closeness to raw materials were factors contributing to this shift.

- Today, the cotton textile industry is concentrated primarily in North Carolina, South Carolina, Alabama, and Georgia.

- Since World War II, cotton’s share of U.S. mill use has fallen significantly.

- During the decline in cotton’s share, humanmade fibres became the major fibres.

- From 1970s growing textile imports (from China) reduced the demand for the U.S. made products.

- In an effort to remain competitive, U.S. mills are adopting labour-saving innovations like automation.

| Market |

|

| Market for byproducts (auxiliary industries) |

|

| Water |

|

| Climate |

|

| Labour |

|

| Technology & Mechanization |

|

Factors responsible for the Localization of the Japanese Cotton Textile Industry

| Land |

|

| Historical aspects |

|

| Raw material |

|

| Transportation |

|

| Market |

|

| Power |

|

| Water |

|

| Climate |

|

| Labour |

|

| Foreign Assistance |

|

Factors responsible for the decline of the Japanese Textile Industry

- Japan’s cotton textile industry began to wane in the 1980s because of increasing labour costs, competition from new synthetic textiles and competition from China and India.

- Many Japanese cotton textile companies relocated to low wage countries such as China and Indonesia.

- Automobile and heavy machinery industry overpowered Nagoya’s cotton textile industry.

- Of late, the cotton textile industry of Osaka has also been replaced by other industries, such as iron and steel, machinery, shipbuilding, automobiles, electrical equipment and cement.

Factors responsible for the Localization of the German Cotton Textile Industry.

| Raw material |

|

| Connectivity and Transportation |

|

| Market |

|

| Technology |

|

| Power |

|

| Water |

|

| Climate |

|

| Labour |

|

Factors responsible for the decline of the German Cotton Textile Industry

- The German textile industry of the 19th and early 20th Century was largely made up of Jews.

- When the Nazi party came to power in 1933, they destroyed the lineage of the Jewish textile trade.

- After the genocide of Jews, the German textile industry was unable to compete with other countries manufacturing in the 20th Century.

- In replacement for textiles, the steel and automobile industry saw great growth.

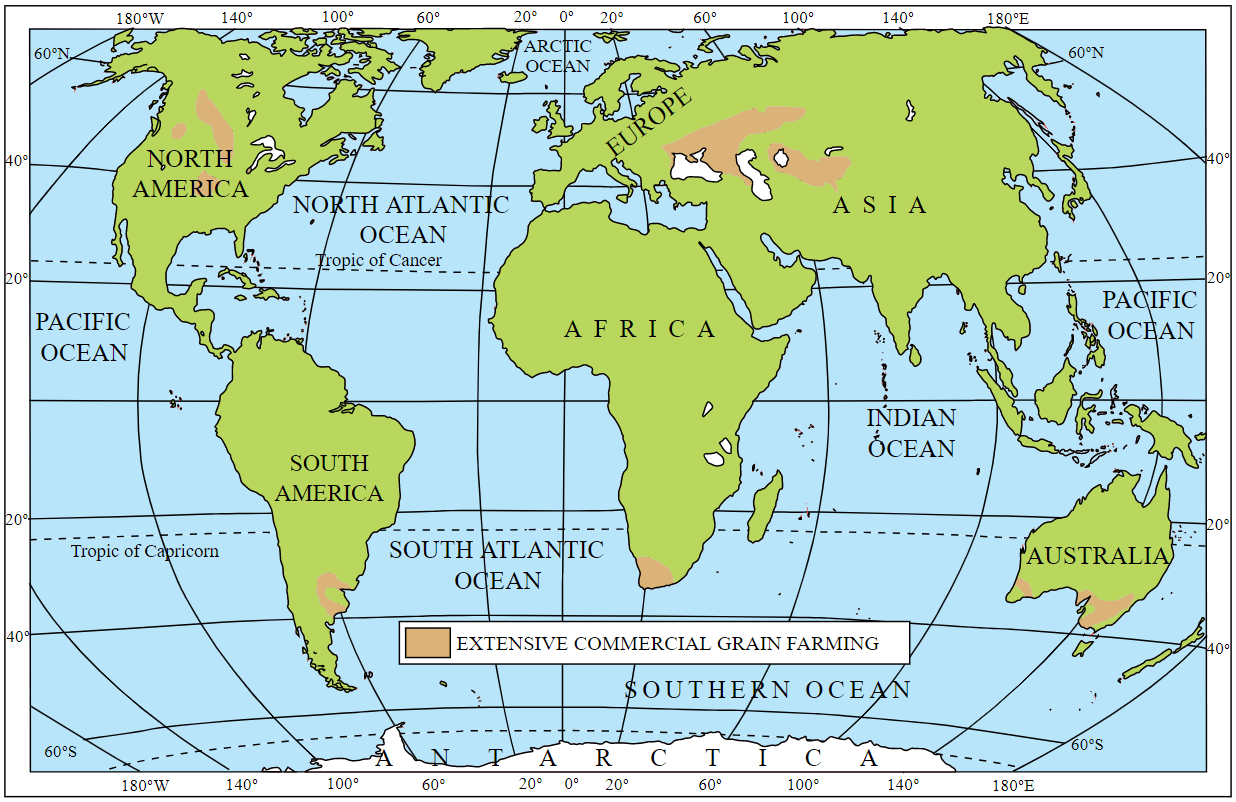

Factors responsible for the Localization of Russian Cotton Textile Industry

| Raw material |

|

| Land |

|

| Water & power. |

|

| Machinery |

|

| Market |

|

| Climate |

|

Factors responsible for the Localization of the Chinese Cotton Textile Industry

- Most of the Chinese cotton textile industry is scattered along the Yangtze River valley region with the highest concentration around Shanghai.

| Raw material |

|

| Connectivity and Transportation |

|

| Capital |

|

| Market |

|

| Power |

|

| Water |

|

| Climate |

|

| Labour |

|

| Economic clout (competitive edge) |

|

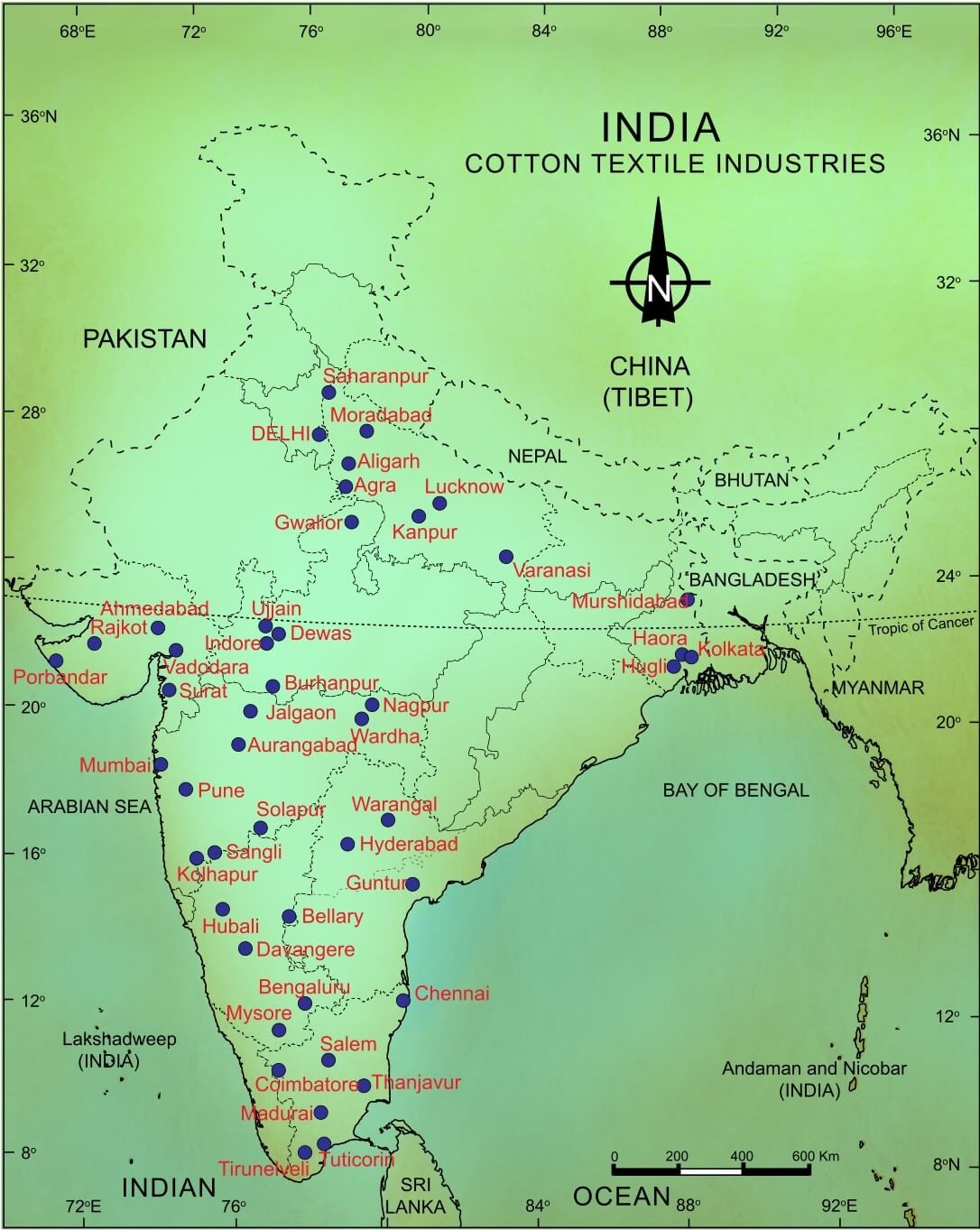

Cotton Textile Industry in India

- In the ancient and medieval times, the cotton textile industry used to be only a cottage industry.

- India was famous worldwide for the production of muslin, a very fine variety of cotton cloth, calicos, chintz and other different types of fine cotton cloth.

- With the beginning of the industrial revolution, Indian cotton textiles industry was decimated due to competition from the mill industry of Britain.

- The first successful modem cotton textile mill was established at Mumbai in 1854 with local capital.

- This industry around Mumbai grew tremendously in the 1870s due to a spurt in demand in the wake of the American Civil War.

- Indian industries made rapid strides during WW I due to a rise in demand for industrial goods.

- The cotton textile industry was concentrated in the cotton belt of Rajasthan, Maharashtra & Gujarat.

- The real spurt was provided by the Indian Fiscal Commission set up in 1921-22.

- This gave protection to industries like iron and steel, textiles, cement, sugar, paper and metals.

- This led to the dispersal of the cotton textile industry away from the main cotton belt.

- The world wars and the Swadeshi Movement favoured the growth of this industry at a rapid pace.

- The industry suffered a severe setback after partition as most of the long-staple cotton-growing areas went to Pakistan while most of the cotton mills remained in India.

- With limited foreign exchange, India struggled to import expensive long-staple cotton from the U.S. and UK.

- With the introduction of Bt Cotton, India is now one of the leading producers of cotton textiles.

The Indian cotton textiles industry has a three-tier structure:

- Low capital but labour intensive handspun khadi sector,

- An intermediate, labour-intensive sector of handlooms and power looms,

- The large scale mill sector which is capital intensive.

- Post partition, the share of the mill sector declined with the growth of power looms and handlooms.

- At present, the bulk of India’s cotton cloth comes from the power loom sector.

- India is now the world’s largest cotton producer, accounting for ~38% of global cotton acreage but only ~23% of global cotton production.

- It is also the second-largest exporter (after the U.S.) and the second-largest consumer (after China).

Factors responsible for the Localization of the Cotton Textile Industry in India

| Raw Material |

|

| Market |

|

| Labour |

|

| The British Factor |

|

Factors responsible for the Localization of Cotton Textile Industry in Mumbai

- Mumbai is called the Cottonopolis of India.

- The following factors favoured the development of cotton textiles industry at and around Mumbai.

| Raw material |

|

| Connectivity |

|

| Location |

|

| Early start |

|

| Market |

|

| Climate |

|

| Power |

|

| Water |

|

| Ancillary industry |

|

| Capital |

|

| Labor |

|

Factors responsible for the Localization of Cotton Textile Industry in Ahmedabad

- Ahmedabad (Manchester of India) is now the second-largest centre of cotton textile industry after Mumbai.

| Raw material |

|

| Connectivity |

|

| Early start |

|

| Market |

|

| Power |

|

| Water |

|

| Climate, Capital & Labor |

|

- In recent years, many textile mills in Ahmedabad have closed down.

- This is primarily due to the emergence of new textile centres in the country as well as non-upgradation of machines and technology.

Others

- Tamil Nadu has the largest number of mills, and most of them produce yarn rather than cloth.

- Coimbatore is the most crucial centre and is known as Manchester of South India.

- Tirupur has some of Asia’s largest garment manufacturing units.

- Cotton textile mills were set up at Kanpur (Uttar Pradesh) based on local investment.

- Mills were set up at Kolkata (Hooghly Region) due to its port facilities.

- It enjoys facilities of a port, humid climate, coal from Raniganj, local labour due to the high density of population and those of dyeing and washing.

- But Kolkata suffers from the disadvantage of being away from the main cotton-producing areas of India.

Issues Faced by the Cotton Textile Industry in India

Cotton crop is highly vulnerable to vagaries of monsoon

- Crop (Kharif crop) is heavily dependent on the erratic monsoon season.

- Approximately 62% of India’s cotton is produced in rainfed areas and only 38% on irrigated lands.

- Hence, India suffers from both overproduction and shortages.

- This makes the supply of cotton to industries highly variable.